For homeowners, timber is popular because of its wide range of design options. Its strength-to-weight ratio allows for spans up to 30 meters long. On the other hand, long spans necessitate more effort to deliver, erect, and install correctly. They may also shake from side to side as they are being braced, and the trusses appear to be quite sturdy once they are braced. "What type of timber is used for roof trusses?" you might ask. You've come to the correct spot if that's your question!

I Will discuss this common question and give you all you need to know about roof trusses.

Definition of Roof truss

Roof trusses are triangular frames built of softwood lumber in various lengths and widths. The triangle structure makes the frame more robust, allowing for smaller planks of wood to support the roof.

Metal connections made of galvanized steel sheets are generally used to assemble the pieces of wood, but nails and braces can also be utilized.

Manufacturers employ sophisticated structural and engineering tools to create timber trusses to match the plans. It's crucial to get precise measurements because of this.

Manufacturers have switched mainly to prefabricated wood frames trucked in from a distance. They're primarily used in residential, commercial, and agricultural buildings.

Roof trusses are also known as frames, industrialized frames, and even rafters depending on the area. However, remember that these terms do not always imply the same thing.

What type of timber is used for roof trusses?

Manufacturers employ computer software to create a wide range of timber truss versions, customized to each job.

Manufacturers can make complicated geometric constructions quickly by manufacturing timber trusses in factories.

Here are some types of roof trusses :

Gable trusses

The King Post, Queen Post, Howe, and Double Howe trusses are some of the trusses that fit into the standard or gable truss category. The four trusses in this gable roof are combined to make a pitched or peaked roof, which is one of the most popular roofs in the United States. The webbing in the truss itself is what distinguishes each of these trusses. The Howe, for example, has more stability than a King Post and can be used to support larger structures that require greater support.

Hip Truss

A hip truss is a popular form of roof used to create a hip roof, which has slopes on all four sides that converge at a point in the middle. Hip trusses are more rigid than gable roofs and are especially useful for high-wind and snowy regions. Hip trusses are similar to gable trusses in that they come in a variety of distinct designs, each suited to a particular architectural style.

Scissor Roof Truss

The scissor roof truss, also known as a vaulted ceiling truss, is one of the most popular truss types. A scissor roof truss has sloping lower chords instead of horizontal ones, forming the apex for a vaulted ceiling.

Attic Truss

Attic trusses, also known as room-in-attic trusses, are sturdy and flexible. They're used in places like garages and sheds that need additional storage space while also providing the ceiling and floor truss for a room within a building's attic. Roof trusses with support webs are used to frame the room's walls. These are most often utilized in storage-concealed structures, but they may also be produced for houses.

Mono Truss

A mono truss is simply one-half of an entire truss. These are highly adaptable, and they may be used to create a roof that gives for more sunshine and visual space. They're frequently utilized in sheds and garages and create extra roof tiers and extensions to an existing roof.

North Light Roof Truss

The North Light Roof Truss has a wide range of web trusses that form triangles within the main truss, much like the Double Howe Truss. North Light Trusses are a classic and cost-effective truss that can span big rooms, such as industrial structures and open concept homes.

Flat Truss

A flat truss is explicitly made for flat roofs. They're constructed similarly to floor trusses with a lot of support because they don't have any slope to shed water or help bear a weight. Flat roof trusses are primarily utilized in commercial settings.

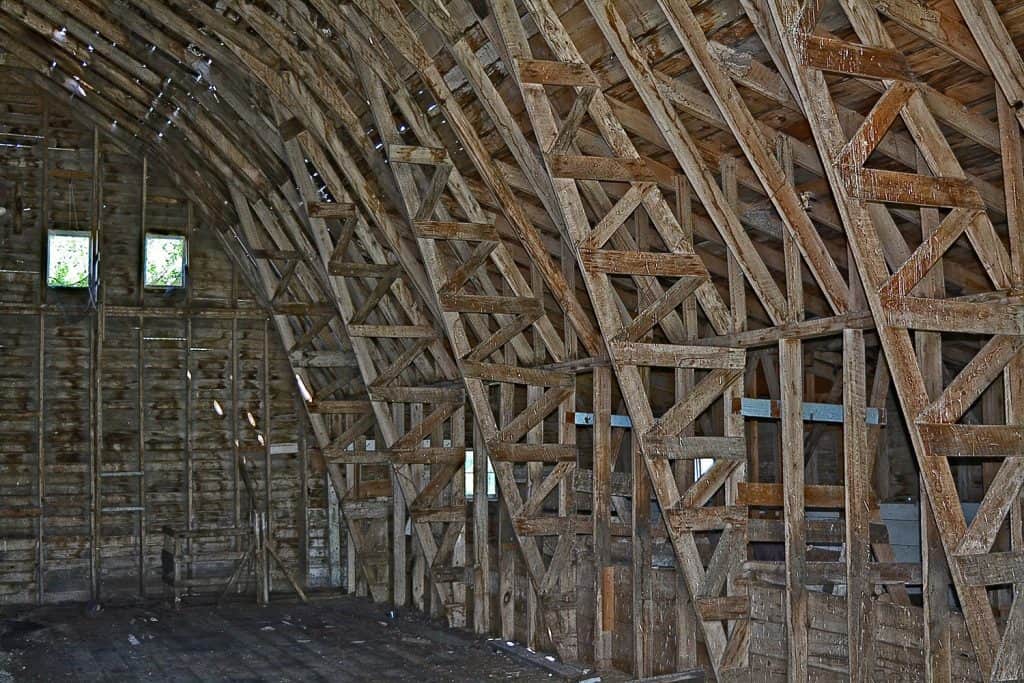

Gambrel Truss

The gambrel truss is most often associated with barns, but it may also be found in various structures, especially as the farmhouse design grows in popularity. Because of its distinctive tall construction, a gambrel truss adds to the vertical space in a form by supporting a wide span.

Raised Heel Truss

The raised heel truss is the last of the three trusses we'll discuss today. These roof trusses are higher than other roof trusses, allowing for easier ventilation and plenty of insulation room. Because these roof trusses are higher than others, they are a popular choice for energy-efficient structures.

Wood dimensions & types

Since you have known, what types of timber is used for roof trusses? Let's learn more about wood dimensions. In the United States, timber trusses are most often constructed of SPF (spruce, pine, and fir) wood.

The size of the roof truss wood beams will vary based on their purpose. Say, the top and bottom chords are usually between 38 x 89 mm and 184 mm (2 x 4 to 2 x 8), while the web members range from 38 x 64 mm to 184 mm (2 x 3 to 2 x 8).

Larger-sized timber, such as 38 x 235 mm and 38 x 286 mm (2 x 10 and 2 x 12) boards, might be used for more complicated tasks like attic trusses and agricultural arches.

Advantages of a Roof Truss

There are several benefits to using prefabricated wood trusses. The following are the most important reasons for their growing popularity in construction and renovation:

Durability

Roof trusses with their triangular form are more resistant to high levels of diverse forces.

An impressive span

The design of the building is highly open and flexible, with no columns or load-bearing walls to obstruct rooms. Roof trusses span 80 feet (24 meters) across, giving plenty of space for significant interior areas without columns or load-bearing walls.

Lightweight

In general, roof trusses weigh between 0.04 and 0.07 kN/m (3 and 5 lb/ft), depending on the size of the components. Their lightness makes them easier to manage, but it also aids in reducing seismic loads in structures with roof trusses.

Precise measurements

Trusses are computer-designed and manufactured using high-tech equipment, ensuring that the final product is consistent with size and measurement.

Low environmental impact

The only long-lasting construction material is timber used to create roof trusses. Furthermore, the wood absorbs carbon that was generated during its development.

Rapid manufacture times

Roof trusses are built in a waterproof facility with automated equipment. Due to these conditions, roof truss suppliers may now provide rapid production times, even for big purchases.

Simple to install

Roof trusses are easily transported by crane and can be installed in a matter of minutes with only a few steps. Roof trusses are generally easy to install, requiring just two persons.

Low cost

Roof trusses are a relatively cheap way of adding extra support to a building. When you use them in your construction project, you'll save money on both the materials and labor involved.