Every structure requires a new roof at some point. This is true throughout the construction process, but all roofs must be replaced at some time. If you need a roof installed, you'll want to know what choices are available no matter when it's done. Flat roofs are typical in commercial structures, and a number of materials may be utilized to cover them. No material is superior in every instance. It's critical to understand the many flat roofing alternatives so that you can pick the finest one for your needs. So among so many Flat Roof Materials, Which is The Best? I will answer that question in this article.

Flat roofs are more common in business buildings; therefore, there are many alternatives. We'll look at the finest and most popular choices to help you choose the best material for your flat roof.

When selecting the appropriate flat roof covering, you must consider several factors, including the design you desire to achieve, the size of your flat roof, the sort of weather it will encounter, and the amount of labor required.

Common Flat Roof Materials

For those looking for flat roof replacement alternatives, there are a number of important things to consider, such as material and installation expenses, life expectancy, energy ratings, ease-of-maintenance, environmental issues, aesthetics, and so on. We've broken down some of the most popular flat roofing products today.

Modified Bitumen

Modified bitumen, often known as a mod bit, is a flat roofing material that has been modified with special polymers to improve pliancy and performance. It's made into rolls with a smooth or granulated surfacing finish and can be hot-applied, cold-applied, or self-adhered.

Although a few manufacturers make bitumen and cement tiles for commercial roofs, most produce bitumen or other forms of asphalt. Bitumens with polyurethane topcoats generally cost more than other business flat roofing materials and may endure anywhere from 15 to 20 years. They're also an exceptionally long-lasting and energy-efficient roof.

The main disadvantage of a bitumen roof that has been modified is its brief lifespan. It's also tough to pinpoint the source of a leak on this sort of roofing material.

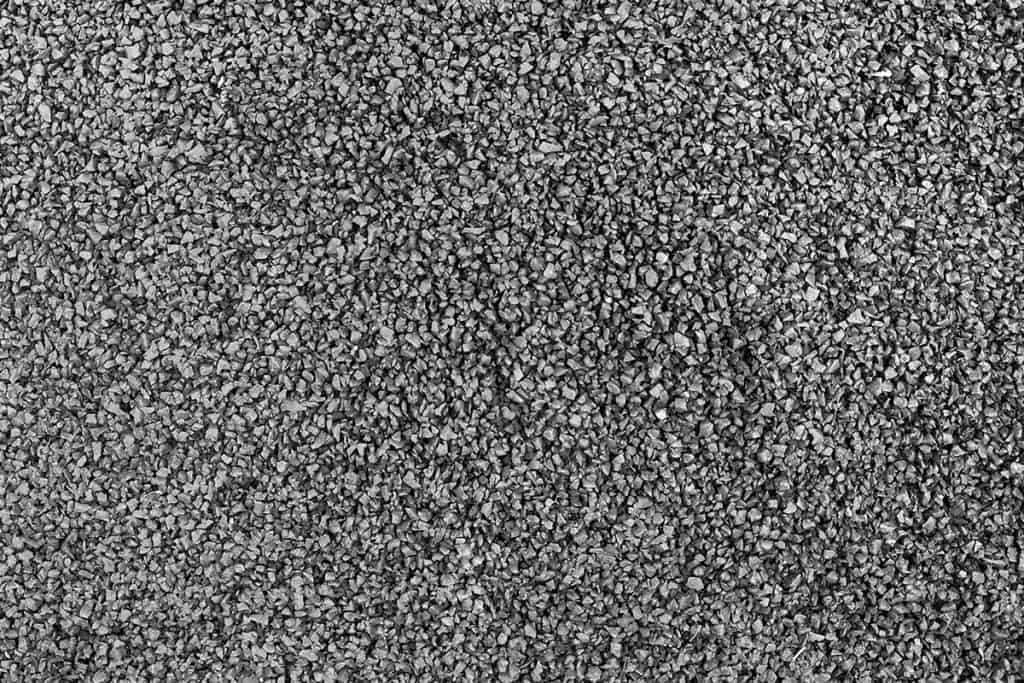

Built-Up Roofs (BUR)

Built-up roofing has several layers added for strength and durability. A built-up roof is one with gravel on the top. It's probably the finest foot traffic roofing material available. It's pretty sturdy because of its numerous layers, and the top layer helps avoid slipping hazards. Built-up roofing is as fire-resistant as it gets. It has a long life span because each level adds longevity, and it seals exceptionally effectively. Hail and debris damage is practically non-existent.

Most of the world's built-up roofs are made up of alternating layers of bitumen (asphalt) and reinforcement fabrics (ply sheets), with a top layer of aggregate, such as gravel, slag, or mineral granules.

On the other hand, the majority of roofs have a lifespan of approximately 15 to 30 years. They generally require little upkeep and give outstanding UV and water resistance. A built-up system's aggregate top layer is also fire-resistant and attractive.

Since built-up roofs require more labor and time to install, they are more costly and take longer. They're also more prone to water and wind damage.

EPDM Rubber

EPDM (ethylene propylene diene terpolymer) is an artificial rubbery material commonly used on flat roofs with low slopes. EPDM roofing has earned a poor reputation for being versatile and efficient due to its use of the term "rubber roofing."

The majority of EPDM membranes are black, although they can also be white, gray, or brown.

The surface of EPDM flat roofing materials is conformable, absorbent, light, and long-lasting. Polypropylene is a type of single-ply membrane that has an average lifespan of about 30 years and costs less than other types of single-ply membranes. Compared to other business flat roofing solutions, they are also simple to maintain.

EPDM is not well suited for every commercial roofing environment due to its numerous benefits. Shrinkage and puncture are common issues with EPDM as it gets older.

It's also important to note that black EPDM roofs absorb more heat than other roofing materials. As a result, they are less energy-efficient than their brightly white counterparts.

PVC Roofing

PVC has been one of the most popular and dependable flat roof materials for decades. It is pretty durable and will endure for several years. It is robust, can withstand any weather condition, and requires little upkeep. It is fire, wind, puncture, and UV resistant. It's one of the most common choices for regions that get ponding since it's so excellent against water. It also comes in a variety of hues.

The negatives of PVC roofing should be mentioned, however. It is not ecologically friendly. It's built from non-recyclable, hazardous materials. It's not always simple to fix or replace it. As for cost, it isn't the most expensive, but it is more costly than most materials.

TPO Roofing

TPO roofing is a relatively new material developed to be a contemporary alternative to PVC roofs. It lives up to its goal of being a more modern replacement for PVC roofs in nearly every regard. It's pretty robust, requires little upkeep, and outlasts (if not longer than) PVC by a long shot. It's not the most inexpensive material available but reasonably priced. It's usually white and reflects UV radiation well because of this. This contributes to lower cooling expenses. Finally, TPO is a light construction perfect for use in almost any structure.

On the other hand, TPO roofing is cutting-edge and has certain drawbacks. It might be more challenging to locate contractors who work with TPO, and because manufacturers haven't standardized everything about TPO, you may get variations in performance. It's also exceptionally challenging to restore a TPO roof because it requires heat welding, which is not flame resistant.

Spray Polyurethane Foam

Spray polyurethane foam is another effective flat roofing system that isn't as popular as the others. This type of roof incorporates closed-cell, multilayer spray polyurethane foam (SPF) insulation and a protective elastomeric topcoat.

The average lifespan of a properly maintained SPF roof is more than 50 years. They act as an excellent insulation barrier for low-slope flat roofs and provide superior energy efficiency and thermal resistance (R-value).

An SPF roof that is well taken care of may endure for more than 50 years. They offer excellent insulation and energy efficiency, as well as thermal resistance (R-value), on low-slope flat roofs.

Not all contractors are equal when it comes to spray foam roofing systems. The installation of this sort of system necessitates a significant amount of technical expertise and experience. Because there is a limited installation time for this system, overspray during application is a risk.

Flat Roof Materials: Which Is The Best?

In general, all commercial flat roofing materials described above are successful roofing solutions. That being said, not all business rooftops are constructed equal. Its suitability will determine the best flat roof material for you in a given roofing installation. Ideally, this should be determined on an individual basis only.

Your priorities and budget will significantly influence which flat roof material is best for you. Hopefully, the explanations above for several flat roof covering choices will help you determine what you need for your project.