Your roof is more than the shingles that show from the street. It's a mix of different roofing materials and parts that work together to keep your home safe from the weather. Roof decking, in addition to all of the other materials, is critical to your roof's success. It's the groundwork for your entire roof system. So, what types of roof decking are used for low slope roofs? If you want to know the answer then you have understand the types wood roof decking system.

That's why anyone who is planning to have their roof replaced (or repaired) should be aware of the significance of the decking on their roof.

The wooden boards that form the framing of your roof are known as roof decking (or roof sheathing). These boards are what your shingles and other roofing components are attached to.

Wood Roof decking is available in two types: plank decking and sheet decking.

Plank decking

Before the invention of plywood, planking was the most common type of decking. This sort of decking is constructed out of lengthy and little wooden boards that are either 1x6 or 1x8 in size.

While this decking style isn't as popular as the covered variety, it is still seen on today's roofs.

Sheet decking

Sheet decking (sometimes called sheathing) is a type of flat wood that forms the flooring of a boat. There are two varieties of sheet decking: plywood and OSB.

Today, the most popular type of decking on roofs is OSB (oriented strand board). It's a flat 7/16" sheet made out of wood chips/strips pressed together.

The size of the plywood depends on the length of the rafters; it's available in various thicknesses (⅜,"½,"⅝," and ⅜"). While OSB is most often utilized, plywood is still widely employed today.

The conventional decking is made of horizontal planks, while the more expensive and custom-crafted version comprises alternating boards in a pattern that resembles brickwork. Both types of sheet decking are excellent choices, but it all depends on your budget and how accessible the wood is.

What types of roof decking are used for low slope roofs?

I often get this question, What types of roof decking are used for low slope roofs? Roofing that is water-impermeable, or weatherproof, and slopes less than or equal to 14 degrees is known as low-slope roofing.

For these roofs, selecting a roofing membrane is a crucial decision for building owners. Because water drainage isn't as adequate as it is on steep-sloped roofs, the roof must endure greater weights and foot traffic.

Because of this, the roofing material that you pick must be waterproof, weather-resistant, and long-lasting.

Here's a quick rundown of the five most common low-slope roof membrane or system classifications to assist you while chatting with your contractor about your roof alternatives.

1.Built-Up Roof (BUR):

The roofing membrane on this house is built up of alternating layers of bitumen and reinforcement fabrics.

- The core of the mattress is generally constructed of glass fiber mats or felts (organic or synthetic) saturated with bitumen by the manufacturer, and they are sometimes known as "felts" or "ply sheets."

- Bitumen is generally asphalt or coal tar heated to a viscosity that can be mopped or mechanically dispersed.

This roof membrane is applied directly to the roof deck, insulation, or over a mechanically affixed base sheet on-site. The outside of this membrane is typically gravel, mineral granules mixed with hot asphalt or a cold-applied adhesive.

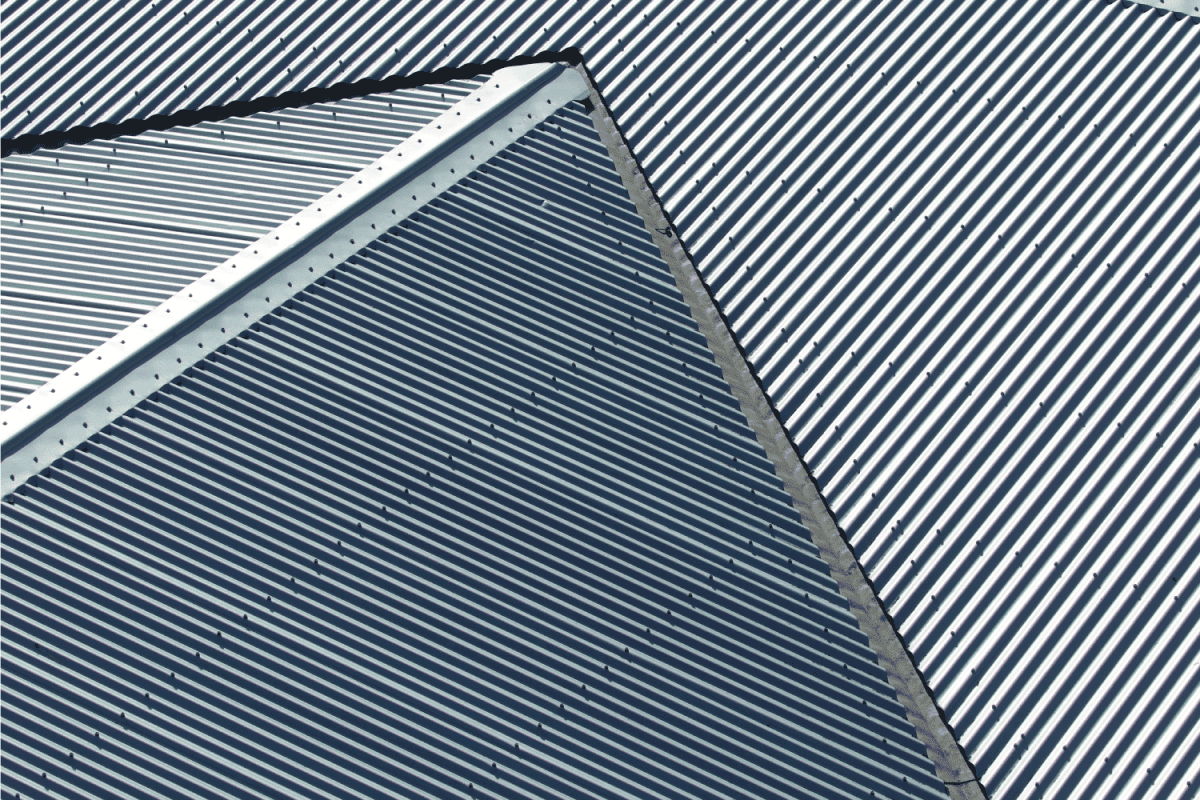

2.Metal Panel Systems:

The longevity of low slope metal roofs is unrivaled. Low Slope Metal Roofs have been a popular roofing material for commercial, institutional, and industrial structures for years because of their capacity to protect against the weather, allow water to drain away from the roof surface, and keep building contents and occupants dry and comfortable.

Metal panel roofing systems may be divided into architectural and structural. Metal panel roofs with structural features are utilized on flat surfaces due to their strength and hydrostatic (water-barrier) features.

These roofs are popular for large factory buildings with significant gaps between structural supports, such as those seen in major manufacturing industries. They are secured to the roof support structures using mechanical fasteners.

Benefits of Low Slope Metal Roofs:

- years of low cost and little upkeep

- Water will run away from a sloped roof more effectively than a flat one.

- Long service life

- Recyclable

- The overall structure is less weighted.

- Low life cycle cost

- You have additional floor area compared to when a steep slope roof is utilized.

3.Polymer-Modified Bitumen Sheet Membranes:

Modified bitumen membranes are prepared bits of bitumen that have been modified with a polymer, such as atactic polypropylene (APP) or styrene butadiene styrene (SBS). The modifiers give the sheets rubbery or plastic qualities, respectively.

Most of the time, they're heat welded together, using a cold adhesive or self-adhering backs. They are most often affixed to an asphalt or modified bitumen base sheet, another modified bitumen membrane, or a 2- or 3-ply BUR.

4.Single-Ply Membranes:

Single-ply membranes are factory-made, single-layer sheets that are frequently divided into two categories:

- Thermoplastic: This material can be repeatedly softened when heated and solidified when cooled.

- Thermoset: Material that solidifies irreversibly by molecular cross-linking after heating.

The thickness of the paper is measured in mils, which equals 0.001 inches. The usual mil thickness is between 30 and 60 mils, although it can be thicker.

Fully adhered, machine fastened, ballasted or protected membrane roof assembly is the most common type of ceiling. Contractors have many options in terms of installation conditions because this allows them to install in any weather.

Spray Polyurethane Foam-Based (SPF) Systems:

The word "waterproofing" refers to a well-draining, waterproof layer of polyurethane or other material (typically cellulose) that is applied to the roof deck.

The foam comprises two compounds: isocyanate and polyol, which are heated and pumped to a roof in precise ratios. A spray gun then combines the two components before spraying them on a surface.

A porous elastomeric coating is usually sprayed on, although it can also be applied by hand or power roller. The top layer makes the foam more weatherproof, UV-resistant, resistant to mechanical damage, and fire-resistant.

Select the type of tile that is appropriate for the weather and traffic your roof will be exposed to while still being cost-effective enough to stay within your budget.